Avoid Contamination In The Lab & F&B Production Site

For every step in your food and beverage process, whether it is storage, production, sampling or analysis, avoiding contamination is key to ensure a safe product for consumption.

Avoiding contamination can be achieved combining several control mechanisms:

- Monitoring of following parameters in the production environment: Temperature, humidity, microbial air contamination, microbial surface contamination

- Cleaning of production areas and quality control labs with efficient, residue-free detergents

- After cleaning, disinfection with a disinfection reagent of choice

- After disinfection, testing for residual disinfectant levels on surfaces

- Efficient sterilisation procedures

Monitoring of production areas

To avoid contamination in a production area, some key parameters need to be monitored such as temperature, humidity, airborne contaminants, etc.

Detergents and surface cleaners

Clean your laboratory from top to bottom with these ecological, no residue detergents.

Reagents for disinfection

Denatured ethanol, hydrogen peroxide, peracetic acid, chlorine compounds, etc. Your disinfectant of choice!

Strips for testing residual disinfectant levels

Test for residual levels of disinfectants such as hydrogen peroxide and peracetic acid to be sure your surfaces are safe to start a new process.

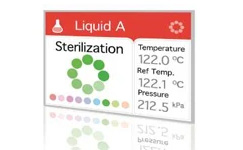

Sterilisation

Autoclaves, sterilisation indicators, disposal bags, autoclave deodorants, foil dispensers. Choose your required product for your sterilisation process.

Contacts

Contacts

Promotions

Promotions